Hans Brunner GmbH

Joint development of a chocolate mould

For the first time the ZDS in Solingen has highlighted the broader topic of chocolate moulds at a conference. A rather spectacular display was put on by Hans Brunner GmbH.

These interesting presentations and demonstrations illustrated all the important basics for the enthusiastic guests, including the development and maintenance of the moulds, their handling in the production process, their cleaning, and much more. The success of this premier event was due in no small part to the participation and spectacular actions of Rudi Schwaiger, Managing Partner of Hans Brunner GmbH, along with his Managing Director Markus Gebhart. Their live demonstration became one of the highlights of the congress.

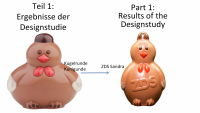

On the first day of the congress Schwaiger demonstrated the wide range of possibilities for how to conduct design studies online. A live video conference linked the auditorium in Solingen directly with the employees at the company headquarters in Glonn, Bavaria. Taking the “Kunigunde” figure from the Brunner portfolio as a template, Schwaiger involved the audience with the aim of creating a brand new individual figure together.

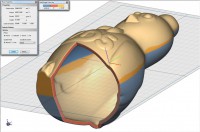

The audience’s wishes and ideas flowed into the CAD construction of this new figure live and online. The Hans Brunner heads demonstrated their expertise in implementing the optical corrections with all of the audience input: factors such as the time limit and adapting the size, specifications such as the minimum weight, breakage reduction, the capacity to add decorative features and slight alterations to the shape of the finished chocolate figure. Finally, the ZDS logo was added to the design.

The audience could follow the alteration process step-by-step on the basis of the “Freeform” system. These steps included scaling at various levels, stylistic changes to the head, eyes and beak and the integration of a widened base to stabilise the figure. This was followed by fine-tuning of the surface and the shell calculation of volume and chocolate weight. Finally, a cut was made to provide a look “inside the figure”. A comparative view revealed how the somewhat round “Kunigunde” figure had been transformed into the unique, sleek “ZDS Sandra” figure.

On day two of the conference, Gebhart surprised the audience with a video recording of the work that had been conducted, along with finished centrifugal moulds and delicious hollow chocolate figures produced at the ZDS on the very same day. With his mould expertise, Mr. Gebhart illustrated the process of creating a stereolithography (SLA) file which was then used as the basis for generating a 3D print file, a 3D PDF file and a finished individual sample. The audience was given an exclusive look at how the stamp is milled, polished and sandblasted, along with the thermopressing of the individual sample and the casting of the plastic replica. In the end the new mould emerged as the Blueflex® Carrier for the ZDS.

The second part of the presentation focused on the layout criteria in the selection and design of the moulds. The criteria included factors such as mould geometry, various mould details, cavity layout, maximum utilization as well as safety, low-stress production, detectable parts, the cooling process and mould identification, and much more. Gebhart also went on to discuss topics including the various cost situations related to injection moulding or thermopressing, a dual-plate tool vs. materials handling tool, and finally cleaning procedures via the avoidance of ejector pins and “dirt pockets”. Finally, the congress attendees expressed their enthusiastic appreciation for the demonstration – and they also enjoyed the sweet, whole milk chocolate “Sandra”.