Mondelez

Approaches to Hygienic Design for chocolate systems

The speech of Dirk Nikoleiski, food technologist at Kraft Foods R&D Inc., business unit of Mondelez international, presented at the ZDS Choco Tec 2014 in Cologne – a synopsis.

The speech of Dirk Nikoleiski, food technologist at Kraft Foods R&D Inc., business unit of Mondelez international, presented at the ZDS Choco Tec 2014 in Cologne – a synopsis.

Hygienic Design is much more than bright and shiny stainless steel installations in a facility, but it isn’t a science on its own either. Basically it’s the application of design techniques that allow for all assets to be cleaned effectively and efficiently in order to minimize the risk of any kind of hazards. Thus it can be considered a prerequisite program within a robust HACCP program and its importance should be recognized by all stakeholders as such.

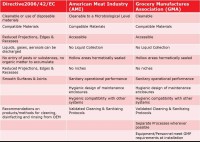

The application of appropriate standards and best practices specific to the sensitivity of products and processes should not be negotiable. The lecture highlights key considerations as regards hygienic design and shares learnings and experiences how to ensure hygienic design is considered for new and modified equipment installations from a food manufacturer perspective. The most important question is: How do you manage pathogen outbreaks, allergens, extraneous matters deriving from equipment, pest infestation risks or cleaning/change over down times, if hygienic equipment design is not adequate? Obligations in the EU

EU Regulation 852 requires food manufacturers to manage food safety risks through GMP and HACCP. Food safety and quality risks may arise from: Biological hazards (microbiological: pathogens, spoilage organisms, toxins, pests); Chemicals (cleaning & disinfecting agents, ancillary substances such as lubricants, and allergens); Foreign bodies (raw materials, pests and materials used in the machinery, like paint). Machinery Directive 2006/42/EC lays down basic hygienic design requirements.

EN 1672-2 and EN ISO 14159 refer to the Machinery Directive and require equipment manufacturers to undertake a risk assessment at the design stage considering its intended use. The equipment manufacturer shall be able to specify the risk level the machine has been designed for and thus its limitation for safe applications.

Nikoleiski presented best practices of cleaning chocolate systems: Dry cleaning still method of choice; flushing with mass/cocoa butter of pipework at elevated temperatures (as high as feasible); scraping & wipe down; dry ice/dry steam. He emphasized: ”Wash down very effective, but should be done only, if water/moisture can be controlled to avoid micro issues”. Best practices in design & layout are dedicated equipment to control allergens (e.g. tanks); Compliance with Hygienic Design principles (cleanable, drainable, accessible, …); Pigging systems; Short distances.

Summary

Hygienic Design evolved over the past years (e.g. wet wash down design for enrobers and depositors), but dry cleaning is still the method of choice in chocolate manufacturing systems. If wet cleaning is applied it shall be controlled through segregation and drying. There is a need for a better understanding how good Hygienic Design looks like (training, guidelines) and awareness how critically important it is for food safety, GMP and efficient cleaning/change over regimes. Hygienic Design should be embedded as a structured approach for new and modified equipment.