Hans Brunner GmbH

Make hollow truffle shells yourself

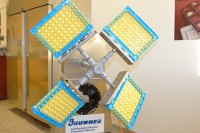

The Glonn-based company Hans Brunner GmbH will introduce the new Easytruffler® system at ProSweets Cologne. According to the company, any confectioner and chocolate manufacturer can use this system to create their own hollow truffle shells, provided they own a spinning machine for hollow figures.

The system is targeted for manufacturers who, up to now, had to purchase hollow truffle shells, as well as manufacturers who wish to provide truffle shells from their own chocolate mass. In particular, bean to bar makers can expand their product assortment while staying true to their concept.The system is flexible, allowing the use of blister packs for ease of use in further processing or for sale. Alternatively, the system can function without the use of disposable blister packs to be more environmentally friendly.

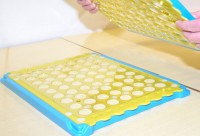

The base system consists of the following components: the Blueflex® carrier with blister holder as the mould bottom, the blister mould, Blueflex® carrier with hard polycarbonate for the mould top, a self-centering punching press to punch the pre-formed, “perforated” opening hole, as well as the blister stabiliser, which supports the blister during the punching. A mask is available as an option. It can be used to hold the shells prior to punching so that the filling can be performed cleanly; the shell can later be closed using the flood method. There is also a variation for the upper section that creates an opening dent, which is ideal for fluid fillings (i.e. liqueurs).

A hollow figure spinner is also necessary, and ideally a dosing apparatus that allows for quick chocolate dispensing. The following areas were emphasised during the product development: The system is easy to operate and can be combined with existing equipment. The hollow figures remain securely seated on the bottom side during opening; this is ensured by a special material geometry. The punching of the openings will be a simple process that does not require a great amount of force.

The ergonomic hole puncher is designed specifically for this application, and it is easy to centre. Thanks to the special arrangement of the punching pins, it requires very little force, so that the shells are not damaged and physical exertion remains minimal.The shells are simple and easy to handle for additional step, like filling, cooling and closing the opening. This enables the use of solely the blister pack for transport. The optional mask allows the shells to be better secured, protected, and finally can be closed easily with the flood method.

Von links: Das Schleudern, die Kugelöffnungen und das Stanzen der Kugelöffnung.

From left to right: Spinning, ball openings, and