NETZSCH-Feinmahltechnik GmbH

Production of 18 µm cocoa liquor with two grinding steps

The Netzsch Group developed the new Tango-System to produce cocoa liquor with chocolate end fineness with a two stage process. In the following case study the company presents this process.

To produce chocolate with high cocoa content, cocoa liquor with chocolate fineness of 18 μm is added directly into the conche. State-of-the-art to achieve this fineness is a three or even four stage grinding process, consisting of one pre-grinder (mostly beater blade mill) followed by two or even three vertical ball mills (chart 1).

Due to the low throughput, which is necessary to achieve the high fineness, there is high wear in the ball mills with the consequence of high iron contamination in the product. In contrast the newly developed 2-stage Tango®–System consists of one MasterNibs, one pump and one horizontal ball mill. No intermediate tanks, no additional pumps are necessary any more.

Cocoa liquor, coming out of the MasterNibs, is pumped directly into the horizontal MasterRefinder, where it is ground to end fineness. The advantages are:

- Less components to be maintained

- Less electrical installation

- Less pipes

- Less space required

- Good access for maintenance and cleaning

Production of 18 μm cocoa liquor with two grinding steps only and iron content < 150 mg/kg

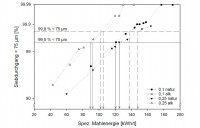

The following charts (chart 2 and 3) show cocoa liquor endfineness produced with the Tango®-System as a function of the specific energy. Alkalized and natural cocoa nibs were pre-ground on MasterNibs, equipped with two different gap sizes of screen: 0.10 mm and 0.25 mm. Subsequent fine grinding in one pass at various throughputs on MasterRefiner delivers an endfineness of up to 100 % < 75 μm.

The two diagrams on the left side in chart 2, which are the most energy efficient ones, show the specific energy consumption of alkalized nibs. Grinding of alkalized nibs requires 35% less energy compared to natural nibs. To produce cocoa liquor with standard fineness of 99.5% < 75 μm, the required energy consumption in case of alkalized nibs is 85 – 90 kWh/t. In case of natural nibs it is 123 – 128 kWh/t. The influence of the fineness of the pre-ground liquor is of minor importance in this range. Only at higher fineness in the range of 99.8% or even 99.9% < 75 μm, the advantage of finer pre-grinding, especially in case of natural nibs, is evident. Pre-ground cocoa liquor on MasterNibs with 0.10 mm gap size and subsequent single pass fine grinding on MasterRefiner requires 135 kWh/t to produce cocoa liquor with 99.8% < 75 μm.

In case of pre-grinding with a 0.25 mm gap screen, the required energy consumption is 150 kWh/t. This is an increase of 9%. To produce cocoa liquor with a fineness of 99.9% the difference is 153 kWh/t versus 168 kWh/t. Usually the fineness of cocoa liquor is described by specifying the percentage of particles < 75 μm. To describe the fineness of cocoa liquor with chocolate fineness, the reference to 75 μm is too coarse. In this case we describe the fineness by using the d90 value. Also here it is obvious, that finer pre-grinding requires less energy.

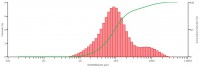

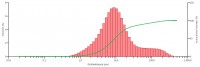

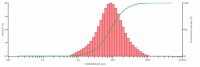

Particle size distribution in case of finer and coarser pre-grinding

Chart 4 and 5 show the typical distribution of preground cocoa liquor from beater blade mills. Typical is the coarse particles foundation, which is even higher and wider in case of using a 0.25 mm screen compared to 0.10 mm. The amount of particles < 75 μm is in the range of 90 resp. 97%.

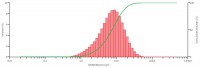

Chart 6 shows the final product made from the pre-ground liquor shown in chart 4. D90 = 17.9 μm – 100% < 50 μm.

Chart 7 shows the final product made from the preground liquor shown in chart 5. D90 = 21.7 μm – 99.9% < 75 μm.

Chart 6 product, pre-ground on MasterNibs with 0.10 mm screen and subsequent fine grinding in single pass on MasterRefiner shows an asymmetric distribution with strong reduction of coarse particles. This shape of distribution is required due to two reasons:

- Production of particles < 5 μm is undesired

- Amount of particles > 15 – 18 μm should be minimized.

For the production of very fine cocoa liquor with chocolate end fineness, the company recommends fine pre-grinding with gap sizes of 0.10 or 0.15 mm.

Iron, tungsten and cobalt content in cocoa liquor

Iron content of the cocoa nibs: 30 mg/kg. Pre-ground cocoa liquor after the MasterNibs: 46 resp. 50 mg/kg.

Fine ground cocoa liquor after MasterRefiner: 110 – 150 mg/kg.

The iron content of the cocoa nibs is due to crushing of the cocoa beans prior de-hulling and due to pneumatic transport. The increase of 16 – 20 mg/kg during pre-grinding is relatively low and depending on the finenessof the screen. The strongest increase of up to 100 mg/kg is during fine grinding in ball mills.

To minimize the iron contamination during grinding, the cocoa processors replace the steel grinding tools by hard metal parts. Usually the following parts are made out of hard metal:

- The beater blades of the beater blade mills

- The grinding arms and

- Grinding discs in ball mills

Of course, there is also wear at the hard metal tools and the ingredients of the hard metal, which is tungsten carbide (about 85%) and cobalt (15%), both heavy metals, are ending up in the product. Netzsch is not using any hard metal tools in the mills of its Tango®-System. Therefore the contamination with tungsten and cobalt is < 0,01 mg/kg.

Due to the design of the Master-Nibs with the drive from the top, it is possible to replace the worn out beater blades within half an hour. By lifting up the rotor out of the hot grinding chamber the exchange of the blades can start immediately and does not require a longer down time until the grinding chamber has cooled down. The very short down time takes the necessity to use hard metal beater blades instead of steel blades. This avoids the contamination of the product with tungsten and cobalt.

How can we explain the low increase of iron content of only 60 – 100 mg/kg during fine grinding?

A homogeneous distribution over the entire height of the grinding vessel is only possible in a small range of the product flow, which is difficult to find out. Also: the throughput is not a free parameter, it is determined by the fineness, which has to be achieved.

Fine products require low throughput, which means that there is a high concentration of balls in the bottom part of the grinding vessel. And this creates high wear, as the balls grind themselves. The result is a high iron content in the product of up to several hundred mg/kg. In contradiction to this situation: the homogeneous distribution of balls in horizontal ball mills.

Conclusion

With the newly developed Tango®-system it is possible to produce cocoa liquor with chocolate end fineness with a two stage process: Pre-grinding with MasterNibs and fine grinding with MasterRefiner in one pass. Finer pre-grinding on a beater blade mill with 0.10 mm gap sieve is recommended due to lower energy consumption. The iron content of this products is less than 150 mg/kg. The influence of the fineness in the pre-grinding stage on the energy consumption is of less importance in case of producing cocoa liquor with standard fineness of 99.5% < 75 μm.