MOTEC Ingenieurbüro Gesellschaft für Industrietechnik, Umwelt- und Arbeitsschutz mbH

New loading system allows for dust-free bag feeding

In the field of bag emptying, the food industry faces various challenges that cannot always be adequately mastered in practice. Thanks to a new bag loading station of Motec, the contamination of workplaces and the slow flow of material during the bag loading of lumpy and cloggy bulk materials in particular are now obsolete.

Not only in terms of worker safety, but also in order to minimize the cleaning and maintenance of the surrounding equipment, it is important that no dust escapes when bagging bulk materials. But even at the current state-of-the-art, this is not guaranteed by every system. The critical point usually is a structurally inefficient dimensioning of the systems, in which, like in a cooker hood, air is sucked only from the bottom to the top. In case of dusts moving in all directions during bag loading, this principle cannot offer a maximum effect.

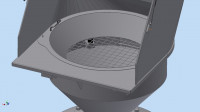

Motec GmbH from Büdingen/Germany makes use of the vortex flow principle to increase the efficiency of its new bag loading station, thus achieving an almost 100 % extraction of the released airborne dust. By means of a vortex extraction hood, the aspirated mass flow rate is

deflected over an edge and set in rotation. The vortex thus produced rotates at a high peripheral speed and causes a uniform, deep dust extraction even over the relatively large area of the entire hood opening. The required mass flow rate is provided by the Motec system via a separate filter unit. By using this vortex extraction hood, the manufacturer succeeds in extracting the airborne dusts already at the point of origin and transporting it away.

Compensating prevents the emission of dust

As part of the design work, the en-gineers of the new bag loading station could also solve the known problems of foreign particles in the product flow and lump-forming bulk by integration of a vibrating sieve directly into the station. Mounted above the hopper by means of rubber buffers, a vibration frame with a clamped sieve is actuated by an unbalance motor. This ensures a loosening of the material already during the bag emptying. In this way, debris is sifted out, and product lumps are effectively dissolved so that the bulk material trickles into the hopper in the station at a constant speed.

In order to prevent the emission of dust between the vibrating frame and the unbalance motor, Motec uses a compensating foil at this point. And also in the areas of maintenance and user-friendliness, the manufacturer leaves nothing to chance. To regulate the fineness achieved, the sieve used is available in various mesh sizes and can be changed in a few steps or removed for cleaning by manually loosening some wing nuts.

The entire system is standardly designed according to the food standard EG 1935/2004 and can be delivered on customer request in an ex-compliant version for Atex areas. Individual adaptation of the new bag loading station to the customer’s requirements regarding surface

quality, connections and dimensioning are easily possible. This is offered by Motec as well as all services, including maintenance and spare parts. •