WDS Winkler und Dünnebier Süßwarenmaschinen GmbH

Special cocoa & chocolate: Mould protection in chocolate production

Die in Eintafel- oder Hohlkörperanlagen zur Formgebung verwendeten Polycarbonat-Formen werden meist mittels Kettentransport durch die gesamte Anlage befördert. Während alle erforderlichen Arbeitsstationen durchlaufen werden, sind die Formen ständig thermischen und mechanischen Beanspruchungen ausgesetzt. Daher ist Kontrolle sinnvoll.

The polycarbonate moulds used in moulding and shell moulding plants are generally conveyed through the entire system by means of a chain transport. While passing through all required workstations, the moulds are permanently exposed to thermal as well as mechanical stress. Thus, control makes sense.

To detect incorrect settings or excessive loads on time, the system should be regularly passed through by a Smart Mould from WDS. The Smart Mould is an “intelligent” mould within a set of moulds, equipped with appropriate sensors to capture specific influencing variables during transport which are compared with online stored target values.

All sensors are connected to an electronics system for recording which is completely self-sufficient. Data is collected in a cache and forwarded to a bidirectional transmitting and receiving unit. This is done via radio connection which enables to permanently retrieve the data online. The measurement electronic is casted in the mould. The used casting material is especially approved for the use in food industry machinery.

Since the transmission to the receiver is done via radio, the function is independent of a WLAN connection. The data sent by the Smart Mould is directly logged. For this purpose and for communication with the line control system, the recording unit is assembled into a WDS switch cabinet. The radio connection is established by rod antenna which is placed at the outside of the switch cabinet.

Due to the different influencing parameters during ongoing production operation of the Smart Mould takes place outside the production process. It is forwarded through the plant in repetitive cycles with predefined and constant plant parameters. The cyclical comparison is based on the data set recorded during a “good run” under specified boundary conditions. The teach-in can take place as needed. The use of the Smart Mould is particularly recommended after carrying out maintenance works or before starting production.

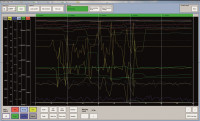

Essentially, the software shows the recorded data of a machine run in terms of curves on a time axis. The machine positions are marked on the x-axis. For each machine position it is possible to fix limits in percent for the excess or the shortfall of absolute values or of analysis results. The defined limit is matched to a colour. •